Team building is a lot of things. Having fun is one of them. And why not combine business and pleasure?

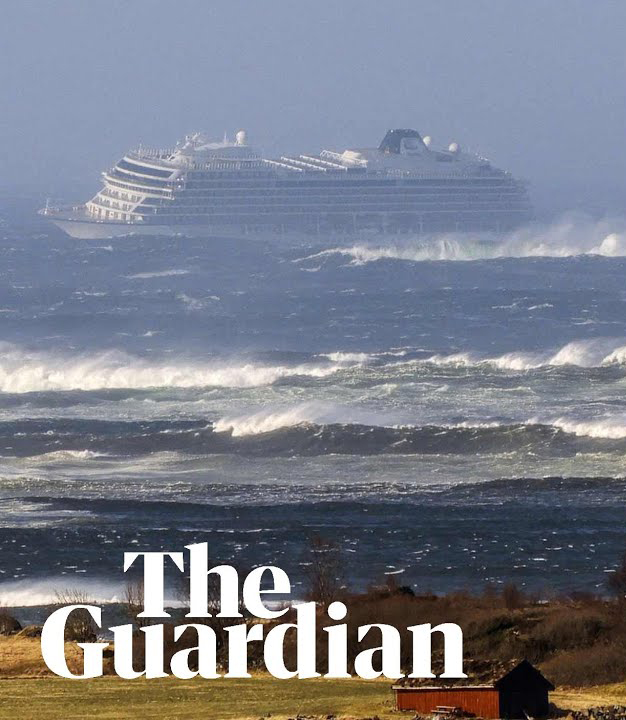

In our full-scale state-of-the art maritime simulators we can take you at sea on-board different types of ships and demonstrate different ship operations or even let you steer and operate the ship on your own along different coastlines and in different harbors. With no risk and a lot of fun!

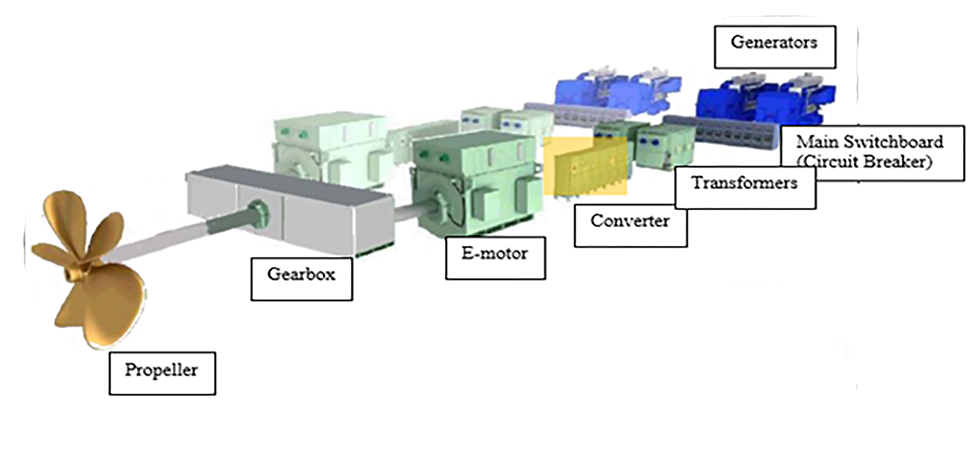

In your daily life at work you might find yourself in situations where you listen to or talk about different types of maritime and offshore operations. Many times, you could wish that you had more insight in these subjects to increase your understanding of your clients’ needs or perhaps go into further details regarding ship capabilities and solutions

We offer a learning arena combined with great fun specially designed for non-operational bodies, brokers, finance institutions, politicians, etc.

Any team building sessions will be tailor made for you and will typically last for less than a day unless you want to go deeper into the subjects.

Did you by the way know that Haugesund is just one hour away from Oslo, 2-3 hours away from Bergen and 1-2 hours away from Stavanger? Take the morning flight and you could be back the same afternoon. Or, you could arrange a team seminar the day before or after and enjoy swinging Haugesund in the evening.

If you fancy this idea do not hesitate to contact Simsea any time.