Kvalitet og effektivitet i maritim trening

STCW (the International Convention on Standards of Training, Certification and Watchkeeping for Seafarers) setter standarden for kompetanse for mannskap på sjøen i en internasjonale ramme. Målet til STCW er å bidra til en sikker hverdag på sjøen og hindre forurensing til sjøs gjennom å ha en etablert felles internasjonal standard for trening, sertifisering og «watchkeeping» for mannskap. Trening av maritimt mannskap er dermed essensielt, og ikke minst da kompetansen til de som trener maritimt mannskap. Hvilken kompetanse skal en lærer/instruktør innen maritim trening ha?

Kunnskap, ferdigheter og holdning utgjør kompetanse

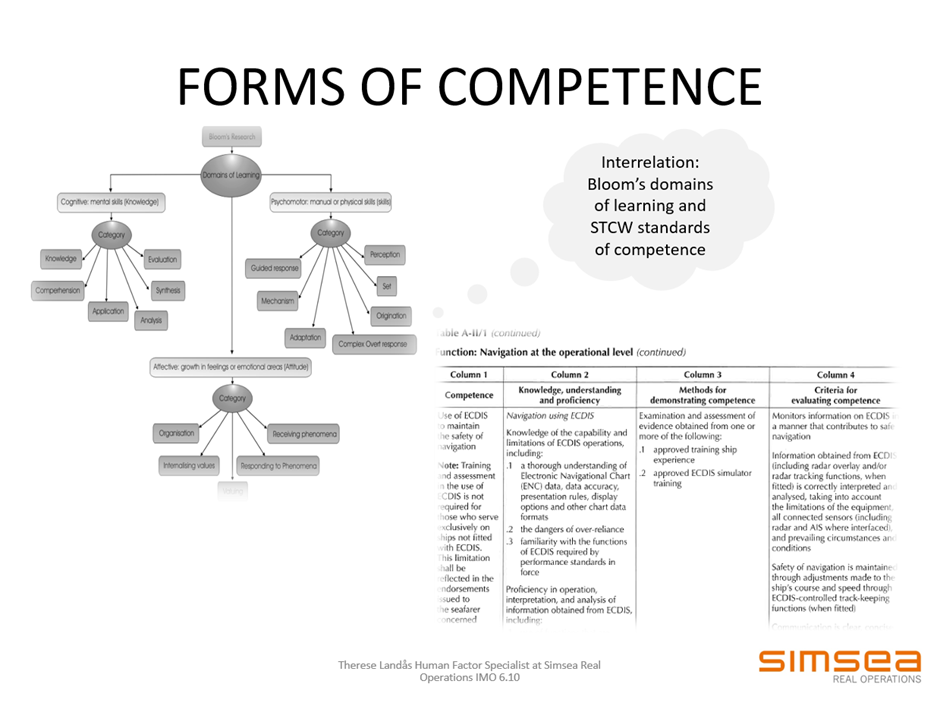

En lærer og instruktør innen maritim trening skal ha kunnskap om læringsprosesser, rolleforståelse og ikke minst en forståelse av den rollens funksjon innen kompetansebasert trening. Kompetansebasert trening, også kalt CBT, handler om å ha forståelse for kompetanse og ulike læringsprosesser i relasjon til utvikling av nødvendig kunnskap og ferdigheter for å utføre sin jobb i maritim organisasjon. En lærer og instruktør innen maritim utdannelse og trening skal ha kjennskap til omfanget av kompetansebasert trening, STCW og den internasjonale rammen som undervisningen/treningen situasjoneres i, samt kunnskap om læringsprosesser.

Didatikk, læren om undervisning, og mellom-menneskelig interaksjon, er sentrale tema på instruktørkurs. Modulkurset IMO 6.09 handler blant annet om planlegging, foreberedelser for effektiv undervisning og kunnskap om ulike metodikker for læringsprosess. Dr. Benjamin Blooms (1956) kompetansedomener er trukket frem av IMO som et verktøy for å forstå «kompetanse» og har en nyttig tilknyttning til STCW egen Standard of Compence.

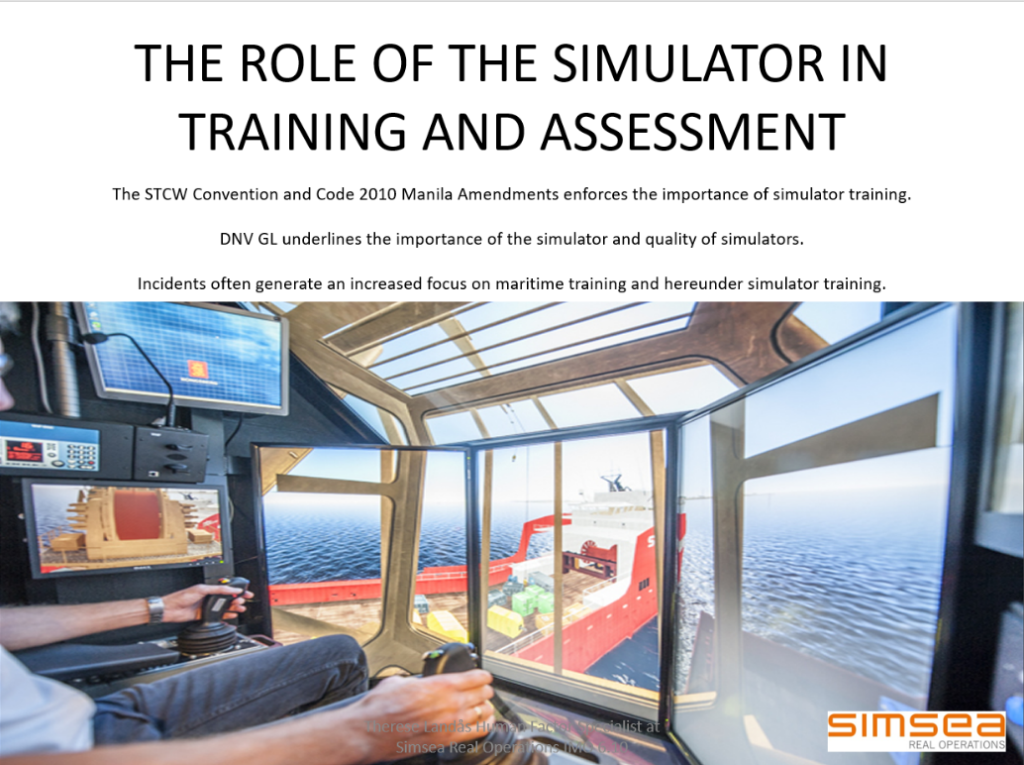

Simulator er et essensielt verktøy i maritim utdanning og trening

I maritim trening brukes simulatorteknologi for å generere kompetanse og som et supplement til teoretisk læringsprosesser. En simulator er et verktøy og har egenskapen i å være en nær replika av et system, fenomen og/eller en prosess. Modulkurset IMO 6.10 har fokus på rollen som instruktør og assessor og har et mål om å utvikle individuelle instruktør-trekk. “To develop a sensitive instructor who fully understands the personality of a seafarer, the importance of simulation in maritime training, and pedagogy skill in order to impart sound and practical training to the seafaring fraternity” (fra modulkurs beskrivelsen IMO 6.10). Kurset gir økt kunnskap om instruktør og assessors rolle i undervisning med simulator som verktøy for lærings- og vurderings-prosesser.

Maritim trening og utdanning handler med andre ord om en viktig, og kontinuerlig, læringsprosess med fokus på kompetanse som verktøy for en sikker hverdag på sjøen.

Vi kjører IMO 6.10 i uke 4 og uke 6 i 2023. For å booke send mail på: Mail@simsea.no:

Felix Anker Klein, PhD i organisasjonspsykologi, and Human Factors Specialist, Test and Assessment Center Responsible hos Simsea Real Operations